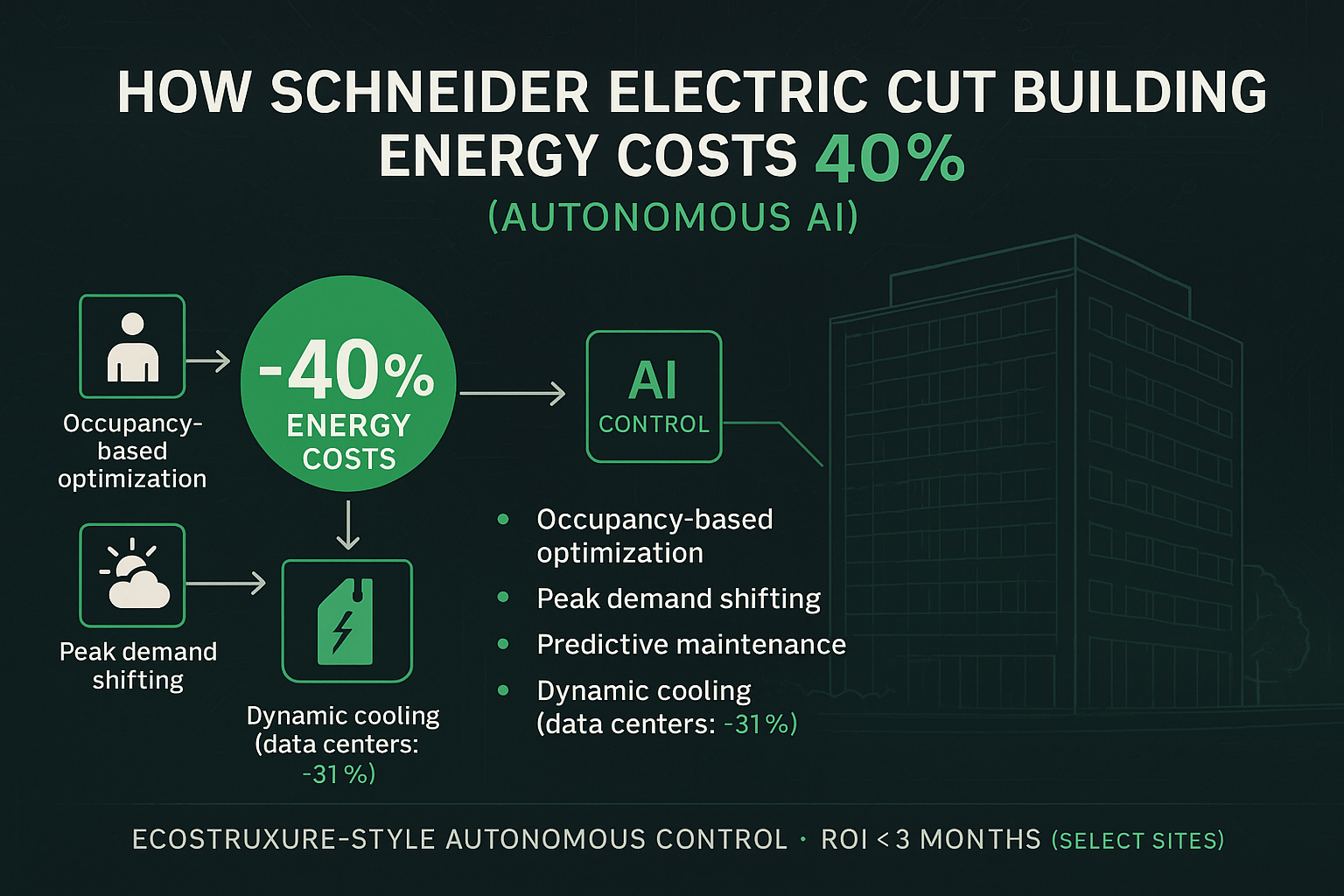

Most building automation systems ask permission before making changes. Schneider Electric’s AI doesn’t. It analyzes equipment usage, occupancy patterns, weather forecasts, and real-time energy prices, then autonomously adjusts HVAC, lighting, and other systems to minimize costs. No human approval required.

The results: up to 40% reduction in building operating costs across commercial, industrial, and residential facilities. Some industrial clients hit positive ROI in under three months. Data centers documented 31% energy cost savings through dynamic cooling optimization that traditional building management systems couldn’t achieve.

The counterintuitive part? The AI doesn’t just respond to current conditions. It predicts future energy needs and proactively adjusts systems before those needs materialize. Your HVAC starts cooling the building 30 minutes before a scheduled meeting because the AI learned that this specific conference room takes 30 minutes to reach optimal temperature. Traditional systems would wait until someone complained about the heat.

The Energy Waste Nobody Sees

Commercial buildings waste energy systematically, not because facility managers are negligent but because traditional building management systems operate on fixed schedules that can’t adapt to constantly changing conditions. The HVAC system cools the entire floor from 8am to 6pm regardless of actual occupancy. Lights run on timers that don’t know three teams called in sick today. Conference rooms get climate-controlled for meetings that got cancelled.

The math is brutal when you examine actual usage patterns. A typical office building might be fully occupied only 40-50% of scheduled hours due to hybrid work, off-site meetings, and varying department schedules. But the building systems run as if full occupancy is constant because fixed schedules can’t differentiate between a floor with 200 people and a floor with 50 people.

Industrial facilities face even more complex energy waste patterns. Manufacturing equipment cycles through different power demands throughout production runs. Some processes require precise climate control while others tolerate wider temperature ranges. Peak energy pricing means running certain operations during high-rate periods costs substantially more than shifting them by just a few hours.

Traditional building management systems can’t optimize across these variables because they operate on pre-programmed rules that don’t adapt to changing conditions. You might set the HVAC to reduce cooling when outside temperature drops, but the system can’t consider that a cloud cover just rolled in, occupancy is 30% below normal, and energy prices spiked due to grid strain from neighboring facilities.

The result is systematic over-provisioning of heating, cooling, lighting, and ventilation driven by worst-case planning. Better to waste energy than risk uncomfortable occupants or production delays. Schneider Electric’s AI breaks this trade-off by optimizing in real-time based on actual conditions rather than worst-case assumptions.

The Agentic AI Architecture

Schneider’s EcoStruxure platform represents a fundamental shift from reactive to autonomous energy management. Traditional systems monitor conditions and alert facility managers to problems. EcoStruxure analyzes conditions and takes corrective action autonomously, only alerting humans when intervention is genuinely required.

The system continuously ingests data from multiple sources: equipment sensors tracking temperature, humidity, air quality, and power consumption; occupancy sensors detecting actual building usage; weather feeds providing current conditions and forecasts; energy price data showing real-time and projected costs; and historical performance data revealing patterns in equipment behavior and energy consumption.

Machine learning models analyze these data streams to understand normal operating patterns for each facility, piece of equipment, and time period. The AI learns that Building A’s north-facing conference rooms require less cooling in summer mornings due to shade patterns. It discovers that Production Line 3 can delay certain operations by 45 minutes to avoid peak pricing without affecting delivery schedules. It recognizes that HVAC system 7 shows early warning signs of reduced efficiency that predict imminent maintenance needs.

The critical innovation is autonomous action. When the AI identifies an optimization opportunity, it implements changes directly rather than generating recommendations for human review. The HVAC adjusts airflow. The lighting dims in unoccupied zones. The equipment scheduling shifts to avoid peak pricing. All happening continuously without facility manager involvement.

This autonomous operation creates optimization impossible with human-in-the-loop systems. A facility manager might review and approve a few optimization recommendations daily. The AI implements hundreds of micro-optimizations hourly, each individually small but collectively substantial.

I’ve observed similar dynamics in algorithmic trading where human-reviewed strategies could never compete with autonomous systems making thousands of micro-adjustments based on real-time market conditions. The constraint wasn’t analytical capability but decision speed and volume.

The 40% Cost Reduction Reality

The headline 40% cost reduction deserves detailed examination because it comes from multiple sources that compound together rather than a single dramatic change.

Occupancy-Based Optimization: Reducing HVAC and lighting in unoccupied spaces typically saves 15-20% of baseline energy consumption. The AI doesn’t just turn off systems in empty rooms. It preemptively reduces conditioning in areas where occupancy patterns predict low usage, then gradually restores comfort before people arrive.

Peak Demand Management: Shifting flexible loads away from peak pricing periods and reducing peak demand charges saves another 8-12%. Industrial facilities with time-flexible operations can save substantially by running energy-intensive processes during off-peak hours when electricity costs half as much.

Equipment Efficiency: Optimizing equipment operation for actual conditions rather than maximum capacity saves 5-8%. Most HVAC systems run inefficiently because they’re sized for peak load but operate at partial load most of the time. The AI optimizes performance across the actual operating range.

Predictive Maintenance: Identifying and addressing equipment inefficiency before failure saves 3-5%. A cooling system losing efficiency due to refrigerant leaks wastes energy while providing inadequate cooling. The AI detects efficiency degradation early, triggering maintenance before major failure.

Weather Prediction: Proactive adjustment based on weather forecasts saves 2-4%. Traditional systems react to current conditions. The AI prepares for changing conditions, reducing energy waste from overshooting temperature targets or catching up after conditions change.

These percentages stack together because they address different aspects of energy consumption. A facility might save 18% through occupancy optimization, another 10% through peak management, 6% through equipment optimization, 4% through predictive maintenance, and 3% through weather-based proactive adjustment, totaling 41% overall savings.

The range of 30-40% reflects facility differences. Buildings with poor existing automation see higher savings because there’s more waste to eliminate. Modern facilities with good baseline management still typically achieve 25-30% savings because AI optimization finds efficiencies human managers miss.

The Three-Month ROI Achievement

Some industrial clients reported positive ROI within three months of deployment. This remarkably fast payback reveals something about the economics of energy waste in industrial operations.

Industrial facilities typically spend 10-30% of operating costs on energy depending on their industry. A manufacturing plant spending $10 million annually on energy that achieves 35% savings reduces costs by $3.5 million. If implementation costs $800,000-1.2 million, payback happens in 3-4 months.

The fast ROI comes from three factors: high baseline energy costs in industrial operations, substantial savings percentages from AI optimization, and relatively modest implementation costs compared to savings magnitude. Energy management AI doesn’t require replacing equipment or major infrastructure changes. It optimizes existing systems, keeping capital requirements low.

The payback calculation also improves because savings begin immediately and compound over time. Traditional capital projects might take months to complete before generating returns. Energy management AI starts optimizing as soon as deployment completes, often within weeks for initial facilities.

Long-term savings exceed initial projections because the system continues learning and improving. First-month savings might be 25% as the AI learns facility patterns. Six-month savings reach 35% as optimization becomes more sophisticated. Twelve-month savings hit 40% as the system masters complex interactions between systems.

This learning curve means early ROI calculations based on initial savings underestimate total value because they don’t account for continuous improvement as the AI accumulates operational data and refines its models.

The Data Center Cooling Revolution

Data centers represent particularly dramatic use cases because they consume massive energy for cooling, have well-instrumented environments generating detailed operational data, and face intense pressure to reduce costs and environmental impact.

Traditional data center cooling uses conservative approaches to avoid hot spots that could damage equipment: over-provision cooling capacity, maintain low temperatures throughout the facility, and run cooling systems at high capacity continuously. This wastes enormous energy but guarantees equipment safety.

Schneider’s AI enables dynamic cooling optimization that reduces energy consumption without compromising equipment safety. The system monitors temperature and airflow throughout the data center at granular level, identifying areas that can safely tolerate slightly higher temperatures or reduced airflow.

The AI also correlates cooling requirements with computational workload. Data center equipment generates heat proportional to processing load. When certain servers are idle or running light workloads, the cooling serving that area can reduce without risk. The AI predicts workload changes and adjusts cooling proactively rather than reactively.

The documented 31% energy cost savings in large data centers translates to millions in annual savings for facilities spending $10-20 million yearly on cooling. More importantly, these savings directly reduce carbon emissions at a time when data center environmental impact faces increasing scrutiny.

The cooling optimization also improves equipment reliability by reducing thermal stress from temperature fluctuations and maintaining more consistent operating conditions. Equipment that runs cooler and more consistently lasts longer, reducing capital costs for hardware replacement.

The Predictive Maintenance Integration

Energy optimization and predictive maintenance create synergistic benefits because equipment degradation affects both reliability and efficiency. A motor with failing bearings consumes more energy while moving toward catastrophic failure. HVAC systems with refrigerant leaks waste energy while providing inadequate cooling.

Schneider’s platform identifies efficiency degradation as an early warning sign of impending equipment failure. A pump suddenly consuming 12% more energy to move the same fluid volume likely has bearing wear, seal problems, or impeller damage. Traditional maintenance catches this during scheduled inspections or after complete failure. The AI flags it immediately when efficiency metrics deviate from normal patterns.

This predictive capability prevents the double cost of energy waste plus emergency repairs. The degraded equipment wastes energy for weeks or months before failure while facility managers remain unaware. When failure finally occurs, emergency repairs cost 2-3x more than scheduled maintenance and production downtime adds additional costs.

Predictive maintenance also optimizes maintenance scheduling for operational efficiency. Rather than maintaining equipment on fixed calendars regardless of actual condition, the AI triggers maintenance based on real equipment state. Equipment operating normally can safely extend maintenance intervals while degrading equipment gets attention before failure.

The practical result is maintenance budgets that accomplish more. The same annual spending delivers better equipment reliability and uptime because resources get directed to equipment actually requiring attention rather than distributed equally across all assets regardless of need.

The Legacy System Integration Challenge

Most facilities can’t replace their entire building management infrastructure to adopt AI optimization. Schneider designed EcoStruxure to integrate with existing equipment and third-party systems, crucial for achieving broad adoption across facilities with diverse installed bases.

The integration approach uses APIs and standard protocols to connect with existing building management systems, equipment controllers, and sensors. The AI layer sits above existing infrastructure, analyzing data from various sources and sending optimization commands back through existing control systems.

This architecture allows phased deployment where facilities can start with their most energy-intensive systems or newest equipment, prove value, then expand to additional systems over time. A manufacturing plant might begin with HVAC optimization, add lighting control, then extend to production equipment scheduling as they build confidence in AI optimization.

Legacy integration also addresses the realistic constraint that most facilities have heterogeneous equipment from multiple vendors installed over decades. Requiring equipment replacement as a prerequisite for AI optimization would make deployment economically impractical. Integration with existing systems keeps implementation costs low while delivering most of the optimization benefits.

The trade-off is that optimization effectiveness depends partly on the capabilities of underlying equipment. Modern digitally-controlled systems can respond precisely to AI commands. Older analog systems might have coarser control options limiting optimization granularity. The AI works with whatever control precision available, though results improve with more responsive equipment.

The Residential Application Scaling

Schneider extended similar AI optimization to residential environments through their Wiser Home platform, though the economics and use cases differ substantially from commercial applications.

Residential energy costs are much smaller in absolute terms than commercial or industrial facilities, so a 40% reduction represents hundreds rather than millions in annual savings. This changes ROI calculations and deployment models. Homeowners won’t invest tens of thousands in energy management systems to save $1,500 annually.

Wiser approaches this through lower-cost deployment using consumer IoT devices and smartphone apps rather than enterprise-grade building management infrastructure. The AI optimization happens in the cloud rather than requiring local server hardware. Installation uses DIY or contractor-installed smart devices rather than specialized systems integration.

The optimization strategies also differ for residential applications. Commercial buildings optimize across hundreds of occupants with statistical predictability. Homes have 2-5 occupants with more variable schedules and preferences. The AI must learn individual household patterns and preferences rather than aggregate statistical behavior.

Residential optimization focuses heavily on comfort and convenience alongside cost savings. Commercial facilities prioritize cost reduction while maintaining minimum acceptable comfort. Homes prioritize personalized comfort while reducing energy waste during unoccupied periods or when occupants tolerate wider temperature ranges.

Despite these differences, the core AI capabilities transfer: learning usage patterns, predicting energy needs, and proactively optimizing system operation. A residential HVAC system that learns your family leaves at 8:30am weekdays and returns at 5:30pm can reduce conditioning during absence while ensuring comfortable temperatures when people are home.

The Continuous Learning Evolution

EcoStruxure’s effectiveness improves over time as it accumulates operational data and refines its optimization models. This creates compounding value where year-two savings exceed year-one savings from the same facility using the same AI platform.

The learning happens across multiple dimensions. The AI refines its understanding of equipment performance characteristics, discovering how specific assets respond to various operating conditions. It learns subtle correlations between variables that aren’t obvious from engineering specifications: how humidity levels affect cooling effectiveness, how wind direction impacts building heat load, or how occupancy patterns in one zone predict usage in adjacent zones.

The system also learns from its own optimization attempts. When the AI adjusts HVAC settings and observes the results, it discovers whether changes produced expected outcomes or if building dynamics differ from initial models. This feedback refines future optimization decisions, improving accuracy over time.

Cross-facility learning provides additional benefits for enterprises deploying EcoStruxure across multiple sites. Insights learned at one facility can transfer to similar facilities, accelerating optimization at newer deployments. A manufacturing company with 20 plants benefits from accumulated learning across all locations rather than each site optimizing independently.

The continuous improvement creates a widening gap between AI-optimized facilities and traditionally managed facilities. Early in deployment, the advantage might be 25% savings. After two years of continuous learning and refinement, the gap widens to 40% because the AI has mastered facility-specific optimization opportunities that human facility managers would never discover.

The Sustainability Compliance Advantage

Energy reduction directly translates to carbon emissions reduction, making AI optimization valuable beyond just cost savings. Companies face increasing pressure from investors, customers, and regulators to reduce environmental impact. Energy management AI delivers measurable emissions reductions with clear ROI.

A facility reducing energy consumption by 35% typically reduces associated carbon emissions by similar magnitudes. For companies with ambitious net-zero commitments, AI-powered energy optimization represents one of the fastest, most cost-effective decarbonization strategies available.

The advantage compounds because energy costs will likely increase over time as carbon pricing becomes more prevalent and fossil fuel constraints tighten. Facilities optimized for minimal energy consumption become increasingly valuable as energy prices rise. This creates hedging value against future energy cost uncertainty.

Sustainability reporting also benefits from the detailed data EcoStruxure provides. Companies must increasingly disclose energy consumption and emissions to investors and regulators. AI platforms generate comprehensive usage data with far greater detail than traditional utility billing provides, supporting credible sustainability reporting and identification of additional reduction opportunities.

The Grid Interaction Opportunity

Advanced energy management AI enables facilities to participate in grid balancing programs where utilities pay consumers to reduce demand during peak periods or shift consumption to times of excess renewable generation.

Traditional facilities can’t easily participate in these programs because manually adjusting operations for grid events is disruptive and unreliable. AI automation makes participation practical by autonomously responding to grid signals without human intervention or operational disruption.

A manufacturing facility might receive a grid signal indicating excess solar generation during midday. The AI can automatically shift energy-intensive operations to capitalize on low pricing while potentially receiving payments for helping balance grid load. Later that day, a peak demand event triggers the AI to reduce non-essential consumption, earning additional compensation.

These grid participation programs provide new revenue streams beyond energy cost savings. Facilities with flexible loads can effectively monetize their flexibility by making it available to grid operators who pay for demand response capacity.

As renewable energy penetration increases, grid balancing becomes more valuable because solar and wind generation create supply volatility. Facilities with AI that can autonomously respond to grid conditions become valuable grid assets, potentially earning substantial revenue from demand flexibility.

The Competitive Pressure Building

Schneider’s public case studies documenting 40% energy savings create pressure across industries. Companies watching competitors reduce operating costs by 30-40% through AI optimization face strategic questions about their own energy management approaches.

The advantage compounds in energy-intensive industries where facilities compete on cost. A manufacturer reducing energy costs by 35% gains 3-5% total cost advantage over competitors in industries where energy represents 10-15% of operating costs. That’s often the difference between profit and loss in low-margin industries.

Facilities that delay adoption face growing disadvantages as early adopters accumulate years of continuous learning and optimization. The gap isn’t static. It widens over time as AI-optimized facilities keep improving while traditional facilities remain constant.

The talent implications matter too. Facility managers who develop expertise with AI optimization become more valuable professionally, creating recruitment pressure on companies slower to adopt. The engineers comfortable working with AI systems can command premium compensation, making talent acquisition challenging for companies behind the adoption curve.

The Implementation Reality Check

Deploying AI energy management at scale requires more than just buying software. Successful implementation involves several elements that take time to execute properly:

Sensor Infrastructure: The AI requires granular data. Facilities might need additional sensors beyond existing building management systems to provide the data resolution necessary for sophisticated optimization.

Connectivity: Reliable network connectivity between sensors, control systems, and AI platforms. Legacy facilities might need networking upgrades to support real-time data transmission.

System Integration: Connecting AI platforms with existing building management systems, equipment controllers, and other operational technology requires specialized expertise in both IT and facility operations.

Baseline Establishment: The AI needs weeks or months of operational data to learn normal patterns before implementing aggressive optimization. Rushing deployment before adequate learning risks comfort problems or operational disruptions.

Change Management: Facility managers and operators must trust AI optimization and understand when human intervention is appropriate. This cultural change requires training and gradual confidence building.

Organizations should expect 3-6 month deployment timelines for initial facilities, with subsequent locations implementing faster as teams develop expertise and repeatable processes.

Your Strategic Response Path

For commercial real estate owners, industrial operators, and facility managers, Schneider’s documented results create clear imperatives. AI energy optimization delivers measurable ROI with payback periods measured in months, not years. Delaying adoption means accepting higher costs and carbon emissions while competitors optimize.

Start with your highest energy-consuming facilities or most sophisticated existing building management systems. These sites offer largest absolute savings and easiest integration paths. Use early successes to build organizational expertise and confidence before expanding to more challenging facilities.

Evaluate vendor solutions based on integration capabilities with your existing infrastructure. Platforms requiring complete equipment replacement are economically impractical. Solutions that work with diverse installed bases provide faster deployment and better ROI.

Establish clear success metrics beyond just energy cost reduction: emissions reduction, equipment reliability improvement, occupant comfort consistency, and maintenance cost optimization. Comprehensive metrics justify continued investment and expansion to additional facilities.

Build internal expertise in AI energy management rather than treating it as pure vendor-managed service. The organizations that develop sophisticated understanding of AI optimization will continuously improve results while those treating it as a black box plateau after initial deployment.

The Future of Facility Management

Building and facility management is shifting from reactive operations to autonomous optimization. The companies that embrace this transition build sustainable cost advantages and operational capabilities that become increasingly difficult for competitors to match.

Schneider proved that 40% energy cost reduction isn’t theoretical. It’s production-ready reality delivering measurable results across diverse facilities. The question isn’t whether AI will transform energy management. It’s whether your facilities will be optimized or left behind consuming energy patterns that increasingly look like waste.

Cutting energy costs by 40% while improving comfort and reliability isn’t just impressive technology. It’s a fundamental competitive advantage that compounds over time.